Vibration Isolation

Vibration Isolators

Vibration isolation is a critical engineering practice focused on mitigating the transmission of unwanted vibrations from a source to a receiver. In built environments, this primarily involves preventing the vibrations generated by mechanical, industrial, or process equipment from transferring into the building structure. These vibrations, if left unchecked, can manifest as disruptive noise, cause structural fatigue, reduce equipment lifespan, and negatively impact the comfort and productivity of occupants. The core principle of effective vibration isolation lies in introducing a flexible element between the vibrating equipment and the supporting structure. This element, known as a vibration isolator, reduces the amount of vibratory force transmitted, thereby minimizing structure-borne noise and resonant vibrations.

Typical Isolated Equipment includes:

- Pumps

- Fans

- Cooling Towers

- Rooftop Units

- Chillers

- Boilers

- Compressors

Spring vibration isolators are a widely used and effective type of passive isolation system. They function based on the principle of creating a low natural frequency system compared to the operating frequency of the equipment being isolated. When a piece of equipment vibrates at a certain frequency (the forcing frequency), a rigidly connected structure will also vibrate at that same frequency, transmitting noise and potentially causing damage. By placing a spring isolator between the equipment and the structure, the system’s natural frequency is lowered. For effective isolation, the forcing frequency should be significantly higher than the natural frequency of the isolated system. This creates a frequency mismatch, where the isolator is able to absorb and dissipate the vibrational energy rather than allowing it to pass directly into the building structure.

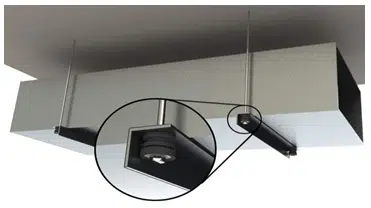

Isolation hangers, specifically designed to suspend equipment, piping, and ductwork, are a common application of spring vibration isolation. These hangers incorporate a spring element, and often a combination of spring and neoprene or rubber, to provide a flexible connection that breaks the path of vibration transmission. Isolation ceiling hangers are particularly crucial for isolating ceiling grid systems and suspended pipe and duct work. Without them, vibrations from equipment connected to or running through these systems would easily transfer into the ceiling structure, radiating noise into the spaces below or adjacent. The spring element within the hanger allows for a controlled deflection under the equipment’s load, and this deflection is key to lowering the system’s natural frequency and achieving effective isolation.

The use of isolation spring hangers is not limited to ceiling systems. They can be employed for hanging various objects where vibration transmission is a concern. The design of these hangers often allows for some degree of misalignment, which simplifies installation and accommodates minor structural variations. The selection of the appropriate spring hanger depends on factors such as the weight of the suspended load, the operating frequency of the equipment, and the desired level of isolation.

Akinco’s Vibration isolators, including spring types, are indispensable for a wide range of mechanical and HVAC equipment commonly found in buildings. Pumps, for instance, generate vibrations due to their rotating components and fluid flow. Isolating pumps prevents these vibrations from traveling through the connected piping and the floor or supporting structure, which can cause noise in distant areas of the building. Similarly, fans, whether part of air handling units or used for ventilation, produce vibrations from their impellers and motors. Spring isolators or hangers are essential to prevent these vibrations from being transmitted through ductwork and the building frame.

Cooling towers and rooftop units are often large, heavy pieces of equipment situated on the roof of a building. Their operation, involving fans, pumps, and compressors, generates significant vibrations. Without proper vibration isolation using robust spring mounts or isolators designed for rooftop applications, these vibrations can travel down through the building structure, affecting multiple floors. Chillers and boilers, typically located in mechanical rooms, also produce vibrations and noise. Isolating these units with appropriate spring isolators prevents the transmission of structure-borne noise and protects the building’s structural integrity over time. Compressors, found in various HVAC and industrial systems, are another significant source of vibration that necessitates effective isolation to prevent noise complaints and equipment wear.

In all these applications, the principle remains the same: interrupt the direct, rigid connection between the vibrating equipment and the building structure using a resilient element like a spring. By carefully selecting and installing vibration isolators with characteristics matched to the equipment’s weight and operating frequency, engineers can significantly reduce the transmission of noise and vibration, leading to a more comfortable, quieter, and structurally sound building environment. The effectiveness of Vibration isolators in achieving this goal is paramount in modern building design and construction.