Acoustic Underlay

It is a peel and stick membrane ideal for reducing sound transmission and as an anti-fracture membrane. It is a rubberised asphalt membrane, which is laminated to a non-woven polyester fabric on the face and a siliconised removable release sheet on the adhesive side.

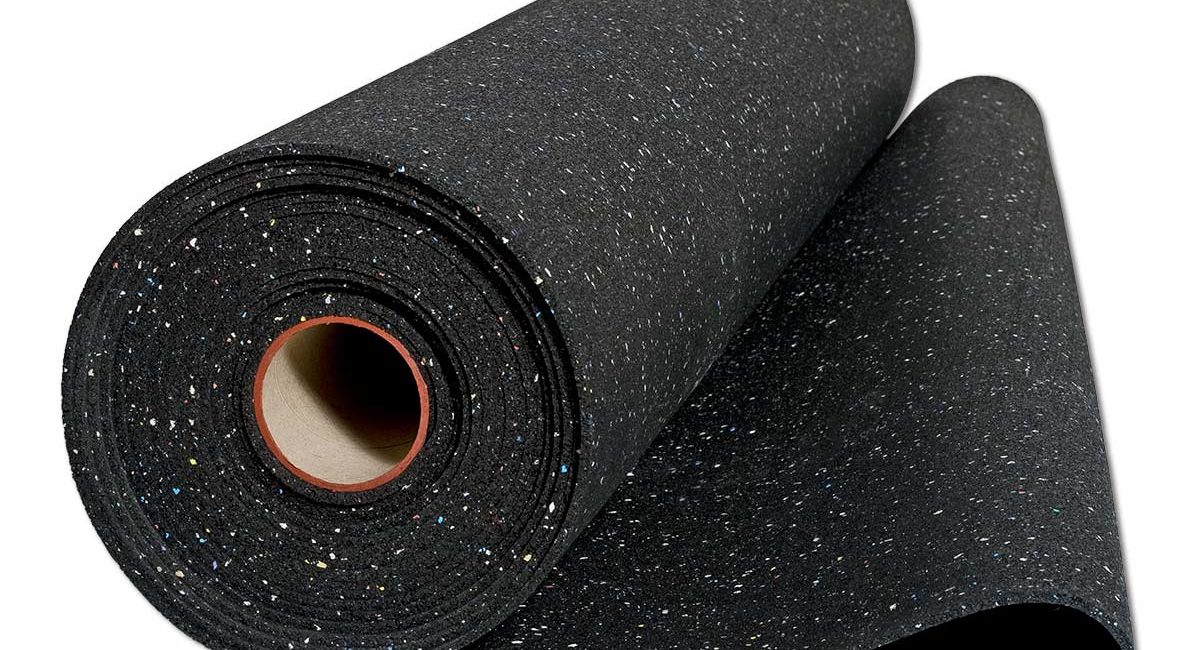

Our impact sound acoustic underlay’s are for every floor covering are high-quality products. They provide high impact sound insulation values, are very durable and low in emissions. Acoustic Underlay is a permanently elastic material and can be supplied in rolls, sheets or molded parts. Acoustic Underlay is suitable for all applications which require attenuation of impact s ound and vibration, durability and resistance to mechanical loads. Acoustic Underlay can be used for a wide variety of sports surfaces, floor covering, impact protection, sheets and tiles for building protection and for impact sound protection, materials for vibration technology and anti-slip mats for securing loads. Acoustic Underlay can be used for a large variety of applications; it is long-lasting, resilient and can be recycled. Our sound underlay products have an excellent ratio between impact sound improvement and structural height with negligible creep behavior, even under high static or dynamic continuous loads.

These layers are installed before the floor covering is added, whether it’s carpet, tiles, floorboards or a floating floor. The underlay is rolled out and glued to the subfloor (usually either a wooden frame or concrete slab) all the way to the edge.

Material Properties

Acoustic Underlay is produced in hundreds of formulations, referring not only to the choice of basic materials and binders but also to bulk density, further processing and other additives. Customized development of Acoustic Underlay variations can be focused on various material properties:

- Material density, Elasticity

- Stiffness, Jounce

- Force reduction, Compression set module

- Compression hardness

- Shock absorption, Impact resistance

- Tensile strength, Dimensional stability

- Abrasion resistance, Elongation at break

- Tear propagation resistance

- Dimensioning ,Shaping, Coloring

- Lamination, Surface profiling, Compression set

- Static permanent load, Load peaks, Reaction to fire, Water resistance

- Water permeability, UV resistance, Air permeability, Thermal conductivity

- Antimicrobial properties, Chemical resistance

- Impact sound improvement coefficient, Vibration technology parameters

Product Data

- Material: fine granulate of recycled rubber with cork and a PU elastomer bonding agent

- Surface: fine granulate texturing

- Density: 700kg/m3

- Thickness: 2/3/4/5/6mm +/- 0.3mm

- Width: 1000mm +/- 1.5%

- Colour: black (granulate), beige (cork)

- Tensile strength: 0.6N/mm2

- Elongation at break: 20%

- Service temperature range: -30°C to 80°C

- Impact sound improvement index ΔLw: 20dB to 28dB

- Impact Isolation Class IIC: 55 to 70

Areas of applications

- Floor covering,impact sound insulating layers in flooring constructions

- Floor covering for outdoor applications,impact protection flooring and elastic components

- Vibration insulation,impact sound insulation, shock absorption

- Building protection mats, vegetation control, etc.

- Protection against point and surface loads

Ref – Altro